Credentials in Aeronautical Machining

New platforms and equipment associated with Aerospace CNC machining must adhere to numerous standards and protocols, which include both domestic and international norms. Manufacturing in the aerospace sector is a delicate process with no wiggle room. Whereas some sectors may afford to have loose standards and polylines, the aviation industry requires absolute perfection and reliability.

Compounds For Aviation Grinding

Automation is a robust technology that may be used to create plastic and metal elements. Furthermore, two substances stand out in the aircraft industry: titanium and aluminum. This is owing to the material's high durability and lightness.

Bonds Of Titanium

Aeronautics employs the most titanium than any other sector in the market. It's simple, and that is why: the alloy has a high potency proportion, is corrosion-resistant, and works well at hot pressures. Titanium has been a standard component in aviation, and its use is expected to grow even more throughout the next generation.

Compounds Of Aluminum

Aluminum alloys are ultralight and tensile-strengthening materials. Whenever aluminum is exposed to the atmosphere, it generates an ionic compound that makes it corrosion-resistant and extremely bendable, making it much easier for CNC machines.

Super Alloys Made Of Inconel

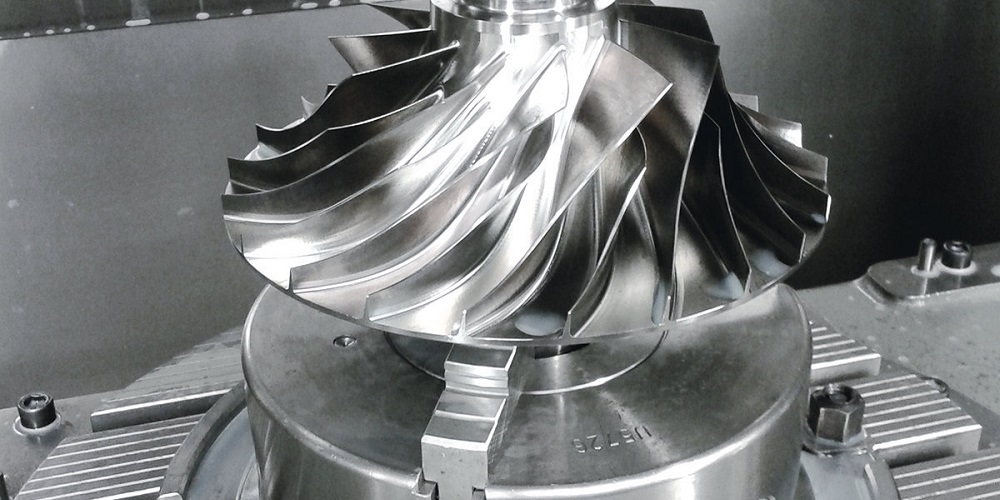

Inconel is a series of ferritic nickel-chromium-based exotic alloys created by the Specialized Metallurgical Corp. Inconel 718, a unique quality of the alloy, was made solely for aeronautical uses. Other aircraft elements that contain it include rotors, ducted devices, and combustion engine devices.

Polymers

Aviation manufacturing can include the use of elevated polymers in complement to materials like titanium and aluminum. Polymers can be a great replacement for metallurgy because of their lightweight, superior pressure and noise sensitivity, insulating qualities, and barrier properties. Metals benefit from their better frequency shielding.

Anodized Equipment For The Aviation Sector

Several commercial aircraft, including critical titanium aircraft engines elements to lightest polymer internal cabin pieces, are manufactured through aviation manufacturing. Reduced products with high durability and delicate characteristics adapt themselves to aviation cutting tools. Various substances can be employed, the most common of which is titanium or aluminum compounds, but additional possibilities such as technical polymers and hybrids are also accessible. Since being poured or extrusion, some pieces may be a thread.

About Aviation Manufacturing, And How Does It Work?

- Milling is the method of separating work pieceswith the help of robot drill bits. On the other hand, metal fabrication is a digital version of machine tools in which processors operate motorized chopping resources to make replacement equipment easily and reliably.

- Aviation Metal fabrication dates back to practically the year when System identification was invented, in 1942. The manufacturing of partition walls and fly covers was one of the first uses of aviation Machinability.

- Numerous aviation elements, including turbines, undercarriage elements, and electronic parts, can now be manufactured. Processing could also be used to restore or alter items and incorporate elaborate designs and etched linguistic content like number plates.

- Throughout product development, aviation manufacturing is also a significant kind of manufacturing. Automated systems are well suited to creating metal aircraft engines that'll be fabricated afterward.